The electrification of Resilience

25ft pocket cruiser

Job #1242 Halvorsens 1967

by Jonathan Stone

So, I bought a boat, with a mate (Mat). It wasn’t our first boat – we had done half a dozen Sydney to Hobarts between us, in offshore racing yachts, also co-owned.

This one – Resilience – is a compact gentleman’s cruiser, timber and traditional, easy on the eyes, right for our years. Like any boat that old, she has a history. She was powered originally by a Chrysler ‘flat’ marine petrol engine, located amidships. Rated 145hp, that engine was powerful enough to put the boat on the plane. By the time we bought her, someone had replaced that with a ~50hp Yanmar diesel, which gave her a maximum speed 10 knots, with much noise and churning of water; but she cruised more smoothly at 6-7 knots and was a pleasure to be on.

But diesel engines are much bigger, power for power, and the engine would not fit midships. Instead, it had been installed aft, against the transom but inboard, driving the original shaft, through a V-gear. This worked well enough, but the engine was too big to fit under cockpit floor, so the cockpit was restricted by a raised cover. And you can see another problem above – a pretty-enough boat, old-growth eucalypt-clad hills (Kur-ring-gai National Park), blue sky, smooth waters – and a long puff of diesel exhaust. On a planet threatened by warming induced by fossil fuels.

The basics of this re-powering of Resilience are 1) the diesel engine, fuel tanks and associated gear were removed and 2) a 15kw inboard motor was installed, driving the original shaft. The fuel tanks were replaced with a 14.4kwh LiFePO4 battery, which should give ~10h at 4 knots, so 40 nautical miles. Range will be less at higher speeds; maximum speed is 7 knots. 3 x 300w solar panels on the roof (still to be installed) should recharge the battery from 20% – 80% in 1 or 2 sunny days. The batteries can also be charged from the grid, or from a portable ICE generator, while under way. There is plenty of room for a second bank of batteries, if needed for range.

In the photo at right, the diesel engine has been removed, and the shipwright, Troy Phielix of Mako Marine Centre at Berowra Waters, is considering how to remove the fuel tanks. You can see one of the tanks under Troy’s right hand. New floor sections were built to replace the raised hatch that sat over the diesel.

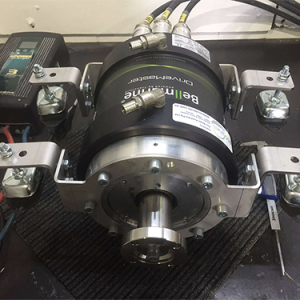

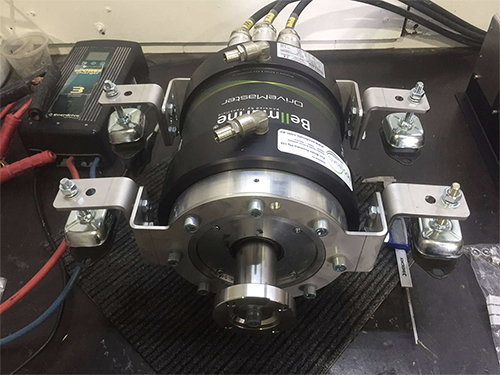

The motor is a 15kw (~20hp) Bellmarine inboard, water-cooled. It weighs 88kg, ~25% of the diesel by weight. It is maybe 10% of the diesel by size and generates 1% of the noise and vibration. The battery driving the motor is rated at 48v. We have retained 3 12V batteries to run the existing 12V systems (nav lights, cabin lights, phone charger, water pumps, refrigerator and more). These are kept topped up by a separate, small solar panel installed some years ago. They can also be charged from the new 48V battery, if needed.

The motor was lowered through the cockpit floor, into the bay that once accommodated the diesel engine, to be mounted, shaft forward. The shaft links with the legacy V-gear that transmits the drive to the original, traditional shaft.

The advantages of electrification include reliability; electric motors are even more reliable than diesel, because they have so few moving parts. A motor is much much quieter and close to vibration-free; and its emissions are zero. If you have solar panels and can wait for the sun, recharging is free; and you can recharge from the sun at a mooring, and while under way – wherever, whenever the sun shines. Two big advantages in this particular retrofit are that the cockpit floor has been restored flat, which is very welcome. And, because the motor is about 1/10th the size of the diesel, a large space has been freed under the cockpit floor, more than enough for a RIB-in-a-bag. The boat is small and the storage welcome.

Disadvantages of electrification are several. In this conversion, we chose a 15kw motor, with which hull speed should be reached at ~75% power. A more powerful motor would have provided greater speed but, above hull speed, range would have been quite short. So maximum speed is down from 10 to 7 knots. Daily range is less than with the diesel and full tanks, unless we bring on board some sort of portable generator. That means burning fossil fuel, which we wanted to avoid. But carrying a camping-style generator would be a reassuring option for the range-anxious, on a longish passage. And the conversion was not inexpensive.

The conversion was done by Mako Marine Centre, at Berowra Waters; we enjoyed a great working relationship. Planning by Brett Tattersall and Troy Phielix at Mako was excellent, and detailed implementation by Troy was thoughtful, excellent. Partly because of the year’s rains, and partly because of the novelty and complexity of the job, the project fell well behind schedule. As I write, the owners remain hopeful the boat will be ready to ‘debut’ at the Timber Boat Festival at RMYC Newport, on November 5 and 6.

But – whether or not we get to the Festival – the hard parts are done and the little boat has a new future. A question for readers: we know that electric conversions have been done on many boats in recent years, and in many places. The question:

Is Resilience maybe the first electric Halvorsen? eHalvorsen I?

The owners would be interested to learn of others.