ATL supplies solution for single shot 80 Litre casting

A recent project at Blackpond Marine relied on ATL Composites’ Technirez R1510 system to breathe new life into the stern tubes of a long-range cruising aluminium superyacht, MV MY WAY.

Named in homage to Frank Sinatra’s most famous song, 35-metre luxury catamaran MY WAY was rebuilt in 1997 specifically for cruising the east coast of Australia. Her Owner and Captain have a 16-year working relationship with GCCM and its onsite trades, and over the years have undertaken maintenance, service and a number of complex refits and equipment upgrades at the shipyard.

On this occasion, the 25-year-old vessel was hauled out for work to repair the stern tubes when it was found that saltwater had caused significant pitting to occur within them.

“The pitting went through the full thickness of the stern tube allowing saltwater from the bearing lubrication to enter the fuel tank,” said Dan Bradford, Naval Architect at Blackpond. “This fault was detected at the conclusion of the yard period. The vessel was scheduled to return to service in time for Christmas, so a rapid solution was required.”

The integrity of the stern tubes is vital to keeping the hull watertight.

The integrity of the stern tubes is vital to keeping the hull watertight.

As Dan explained: “In small ships and recreational vessels that almost exclusively use propeller shaft bearings lubricated with saltwater, these bearings are housed within a stern tube and saltwater is pumped into this tube, typically after being heated by engine’s heat exchanger.

“While aluminium is considered resistant to corrosion, in environments such as stern tubes where the supply of oxygen is limited or the water supply is heated, pitting corrosion can occur aggressively deteriorating localised areas. If this pitting is not addressed, the loss of material at the bottom of the pits can break through causing failure to the watertight integrity of the hull.”

Corroded and pitted plate is typically repaired by replacement – cut out the damaged material and weld in new material. This is difficult on stern tubes since re-welding affects the shaft alignment. Stern tubes in catamarans can also be integrated into the keel structure, so access is difficult.

Dan continued: “In this case, the problem was further complicated by the stern tubes being inside integral diesel tanks. The diesel had protected the outside of the stern tubes, but the inside resembled the surface of the moon!”

BlackPond designed a novel solution with Sweep Marine Services and Watsons Engineering in consultation with ATL Composites.

“ATL Composites have always been our go-to supplier for all things composite, especially when the problem is out of the ordinary.”

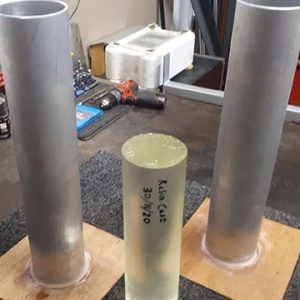

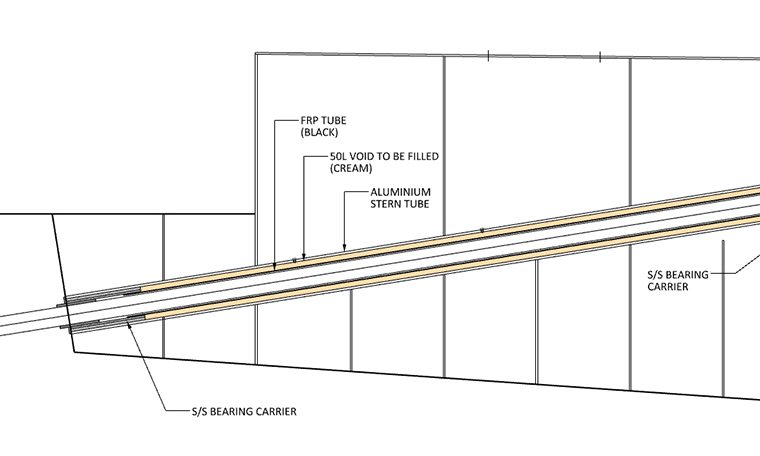

Rather than the intrusive and time-consuming replacement of the aluminium, BlackPond engineered a solution that involved a GRP liner tube inside the existing aluminium with epoxy cast to the gap. Sweep Marine Services cleaned and prepared the surfaces – a challenging process within 160-millimetere diameter tube over the 4-metres in length.

Watsons Engineering machined the GRP tube for a neat fit at the bearing carriers and a 20mm wall thickness for the casting. The tube was then sealed at the ends with ATL Techniglue.

ATL Composites provided Technirez R1510, a special casting epoxy with a super low, water-like mixed viscosity and a very slow set time measured in days, to allow for a slow and controlled pour, minimal shrinkage and negligible exotherm.

“We cast 2.5 litres of the Technirez R1510 into a 100-millimetre tube to test the product,” said Dan. “This adhered well and performed as expected providing confidence to proceed with the final pour of 80 litres.”

Thanks to a combination of ingenuity, inspired design and ATL Composites’ quality products, MY WAY was back in the water for Christmas and reports are that there has been no water ingress and no unwanted noise or vibration.

More at www.blackpond.com.au