Fibreglass Boat – Rotten Transom?

Fibreglass motor boats are some of the best designed and most desirable boats on our Australian waterways. They last practically forever and still look good when tinnies the same age look dull and tired.

The downside is that many older fibreglass motor boats suffer from a defective soft and often rotten transom.

If it is not repaired then eventually the transom is likely to break and possibly drop the motor overboard into the water or maybe onto the road when the trailer goes over a bump. Holes might also open up leading to the boat sinking. Not good.

A professional transom replacement is expensive and while the boat yards do a great job, the cost could add up to more than your old boat is worth. The alternative is doing the replacement yourself and with the latest epoxies and glues, that’s not as difficult as it sounds.

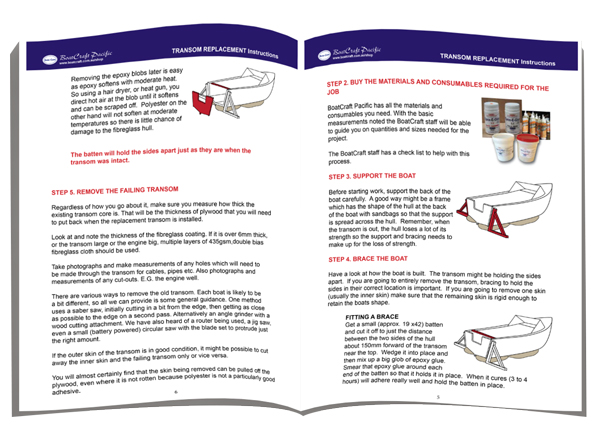

Essentially what you are doing is removing the plywood in the old transom and replacing it with a new piece the same shape and thickness, which is coated with epoxy to make it waterproof and rot resistant.

Depending how far gone the old transom is, you may be able to retain the outer fibreglass skin or simply cut the old one out and replace the transom completely and add a new fibreglass skin as well. The whole thing is then glued into place, faired and painted and your boat is ready for action.

You will have saved your boat and some money and had the satisfaction of a job well done.

BoatCraft Pacific supply the materials including the latest epoxy resins, glues, marine grade plywood and fibreglass cloth and tape for the construction and installation of a new transom.

They have even produced a FREE on-line Instruction e-Booklet for the Transom Replacement which is available on request. (A printed copy is available for $5.00).

They have even produced a FREE on-line Instruction e-Booklet for the Transom Replacement which is available on request. (A printed copy is available for $5.00).

BoatCraft staff have a check list of materials for the job and can provide everything you need based on your transom size and thickness. (Phone 1300 148 442)

The entire package and the Instruction Booklet can be delivered nationally via or collected at BoatCraft distributors in every State.

THE TROUBLE WITH TRANSOMS!

Transoms in fibreglass boats are almost always a thick piece of plywood with fibreglass skins on both sides. Their strength matters because the outboard motor is mounted on it. The plywood provides most of the strength, while the fibreglass skins are quite thin and have little strength.

Unfortunately, in time, the plywood starts to rot and lose its strength. The early symptoms are that the transom starts to move a bit when the motor is used, maybe it feels a bit soft in some places or when tapped it gives a dead noise rather than a ring sound.

All plywood transoms in all polyester fibreglass boats will suffer this fate, sooner or later.

The reason the transom plywood rots is that polyester fibreglass allows a small amount of water to pass through it. That is, it is slightly permeable. As a result, the plywood absorbs water and when its moisture content reaches about 20%, the dry rot fungal spores (which are lying in wait in all timber) become active and start to consume the timber.

To explain a bit more, timber which is kept dry has a moisture content of about 12%. At this moisture content, dry rot spores are inactive. Almost all fibreglass boats are made using polyester fibreglass because it is an economical way to build a boat which is strong and will resist UV light and last for a good number of years. Polyester fibreglass boats are tolerant to less than perfect storage and lack of detailed care.

The manufacturing process needs to use some timber to achieve the right hull shape. The transom is one place where it would be very difficult to build the strength without using a sheet of plywood. The stringers (the reinforcements which run along the bottom of the boat) are another place where wood is usually used, and often the floor will also be of plywood.

While polyester fibreglass is a great material to build a boat, it has some limitations. The most important for us is its permeability. Over time, water molecules forced their way through the polyester until the reach the timber inside.

Dry rot is not a good name for the phenomena. The spores need moisture to function. The timber moisture content needs to rise to 28-30% to initiate the attack, but once underway, it can remain active with a timber moisture content of 20%. 20% timber moisture content will occur in timber which is left in a relative humidity of 86% or above.

Once timber starts to decay, it is very difficult to repair. Amongst the reasons for this is that the strength loss due to the rot is permanent and unless the conditions which caused the rot to start are changed so that it cannot restart, it will recur.

Of course if any holes have been drilled through the transom, and not treated to prevent water ingress to the plywood, they will provide an even speedier means for water to get in and start the rot process.

How to fix it for once and for all?

The only effective way to fix a rotten transom once and for all is to cut the soft, rotten transom out in its entirety and to replace it with a new plywood one which has been coated in epoxy. Epoxy is a great coating for this application as it is very much less permeable than polyester, so provided the replacement plywood transom is fully coated in epoxy and care is taken to seal any holes drilled through it, it should last for a great many years.

Trying to just cut out or reinforce the rotten bit simply leaves the rest of the old transom in place, rotting away, and before long it too will fail, and then probably the whole lot, repair and all will fail.

Putting a rot killing material into the rotten wood might kill the spores in that vicinity, but it won’t restore the strength, and most of those preparation only provide a temporary stop to the rot as they will leach out and leave the wood unprotected once again.

Putting a second, new transom in behind the existing transom can restore the strength of the transom, provided it is properly attached to the hull. Of course this new transom will also rot in due course unless it is properly protected. (The best way is to coat it with epoxy and then a paint to protect the epoxy from the sun’s rays.)

Coating the replacement transom in polyester fibreglass means you will finish up with a rotten transom again in no time. Only epoxy coating the new plywood can really prevent the ingress of water and so prevent a recurrence of the rot.

Gluing the replacement transom in place needs good epoxy glue. “Epox-E-Glue” supplied by BoatCraft is one of the best and does not shrink when it cures and pull itself off the glued surface.

For further information on transom replacement we suggest you contact BoatCraft Pacific on 1300 148 442. Their staff will be happy to help and advise you as you get on with replacing the old transom and transforming your old boat.